BritAS at the K 2025 – Hall 9, Booth B20

- At the booth: ABMF 1600 – the internationally highly demanded automatic band melt filter for highest regranulate quality

- World premiere: Introduction of the BritAS Asia EASY LINE melt filter

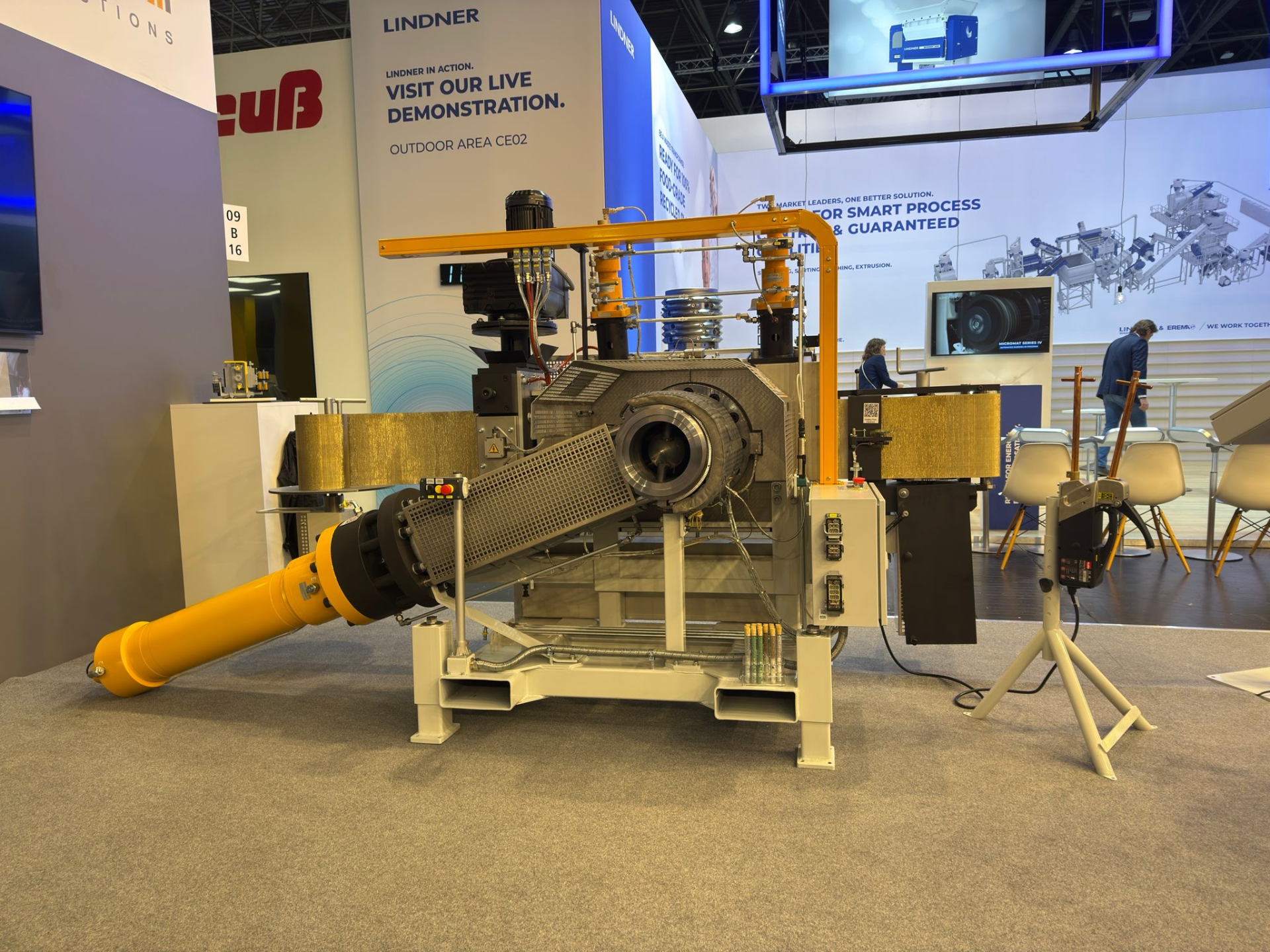

During the K 2025, at the booth, BritAS Recycling-Anlagen GmbH presents an ABMF 1600 of its proven product series automatic band melt filter. Internationally highly demanded, it stands for fine filtration of plastic waste as well as sustainably improved regranulate quality.

„Some of our customers additionally use a second ABMF at the end of a machine line to increase the quality of the regranulate specifically “, explains Heiko Henss, CEO BritAS Recycling-Anlagen. The ABMF series convinces by easy integration, safe operation and a constantly high process stability. During each filter change, fresh screen mesh is automatically inserted. Thus, the regranulate quality remains constantly high while contaminations can be removed efficiently and with a minimum loss of melt. During the filter change, thanks to an integrated intermediate buffer, the upstream extruder continues to run permanently – this guarantees continuous production and process safety.

ABMF Series – ultrafine filtration up to 20 µm

The BritAS ABMF technology is especially appreciated because of its high filter fineness of up to 20 µm, its homogenous melt quality as well as the optimized flow channel, which improves the melt flow without causing material stress. The support plate design additionally provides higher throughput rates at lower pressure build up and allows gentle processing. „At the same time, the used screen belts with Dutch weave guarantee low operating costs at high output – our ABMFs are ideal for heavily contaminated materials and high throughputs “, says Henss.

At the K, only shown on a model scale, with the further optimized ABMF-PET-C Continuous, BritAS offers a new generation within the series, which is especially designed for low-viscosity materials such as PET. „The PET-C is based on our established and recognized ABMF technology; however, it was comprehensively improved and made ready for series production. In bottle-to-bottle applications the filter, which is equipped with dual cavity technology, convinces with highest regranulate quality, filter fineness of up to 20 µm and minimum loss of melt of less than 0.5 percent “, gladly explains Heiko Henss.

The ABMF series stands for easy to integrate and user-friendly technology, constant product quality, efficient cleaning and high efficiency – a perfect combination for recycling processes worldwide.

World premiere – BritAS Asia EASY LINE ABMF-0300-05 melt filter

At the booth of the affiliated Indian company NGA Plastic Technology (Hall 10, Booth B01), under the brand BritAS Asia, BritAS initially presents the simplified belt melt filter EASY LINE ABMF-0300-05 – for the filtration of contaminations in plastic waste. The BritAS Asia filter is designed for small throughputs and allows the production of high-quality regranulate. It is based on the proven BritAS technology, however, for the EASY LINE series, it was simplified. The novelty is characterized by low operating costs, fully automatic operation and a rugged, efficient design. As of now, the BritAS Asia ABMF is manufactured in India, and sales will be handled by both companies.

BritAS is part of the NGA Next Generation Analytics Group,

NGA Group at the K 2025:

BritAS Recycling-Anlagen – Hall 9, Booth B20

COLLIN Lab & Pilot Solutions – Hall 9, Booth B16

COMELT – Hall 1, Booth C88

NGA Plastic Technology – Hall 10, Booth B01

8-15 Oct 2025