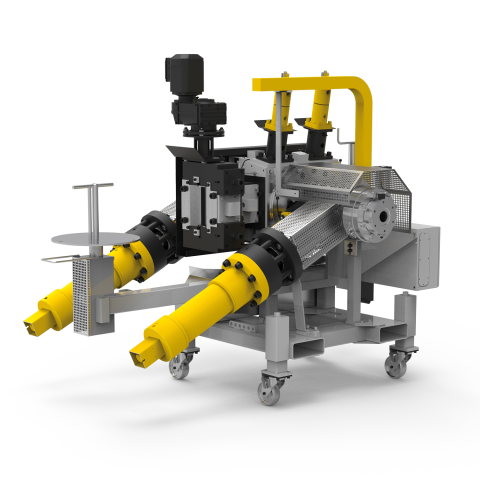

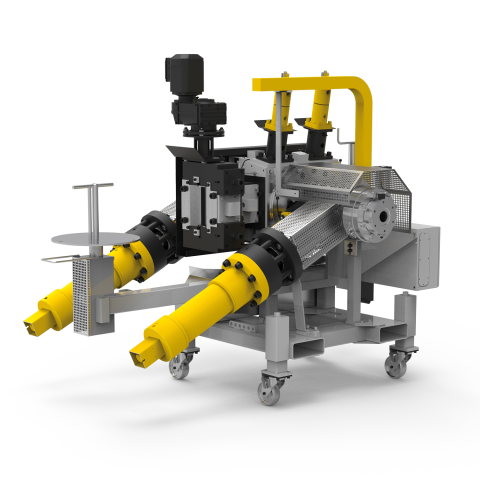

The downstream unit guarantees a continuous melt flow.

In order to filter contaminations effectively and efficiently out of plastics waste, in case of the BritAS filter, the filter fabric is fully-automatically changed. Thus, the regranulate quality remains constantly high and the contamination is discharged out of the machine with a very low loss of melt. By an intermediate container for the melt, the upstream extruder is permanently running.

Suitable for post-consumer and post-industrial plastics waste and agricultural film..

Certified. Certified according to EN 15343ff, excellent regranulate characteristics.

| BritAS Filter | Filter area [cm2] | Filter area [sqin] | Volume [Liter] | Volume [gal] | max. output [kg/h] | max. output [lbs/h] |

| ABMF-C-0570-07 | 570 | 88.4 | 7 | 1.8 | 900 | 1985 |

| ABMF-C-0570-09 | 570 | 88.4 | 9 | 2.3 | 1200 | 2646 |

| ABMF-C-0570-12 | 570 | 88.4 | 12 | 3.1 | 1500 | 3308 |

| ABMF-C-0750-09 | 750 | 116.3 | 9 | 2.3 | 1200 | 2646 |

| ABMF-C-0750-12 | 750 | 116.3 | 12 | 3.1 | 1500 | 3308 |

| ABMF-C-1050-09 | 1050 | 162.8 | 9 | 2.3 | 1200 | 2646 |

| ABMF-C-1050-12 | 1050 | 162.8 | 12 | 3.1 | 1500 | 3308 |

| ABMF-C-1050-15 | 1050 | 162.8 | 15 | 3.9 | 2000 | 4410 |

| ABMF-C-1050-19 | 1050 | 162.8 | 19 | 4.9 | 2500 | 5513 |

| ABMF-C-1600-12 | 1600 | 248 | 12 | 3.1 | 1300 | 2867 |

| ABMF-C-1600-15 | 1600 | 248 | 15 | 3.9 | 1600 | 3528 |

| ABMF-C-1600-19 | 1600 | 248 | 19 | 4.9 | 2000 | 4410 |

| ABMF-C-1600-25 | 1600 | 248 | 25 | 6.5 | 2700 | 5954 |

*Output values for LDPE depend on material and contamination.