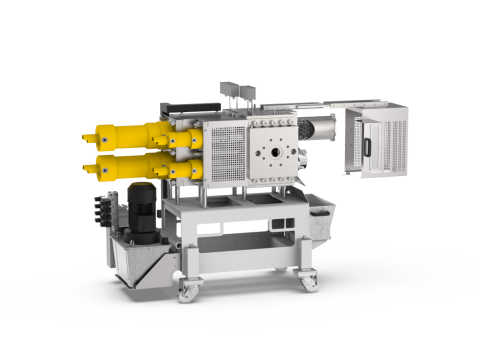

For applications with higher levels of contamination and frequent screen change intervals, the continuous piston screen changer with back flush function CMF-BF is used.

This filter type is able to clean the screens automatically. The back flush attachment includes two pistons which automatically perform the back flushing process.

When a filter change is required, one of the two back flush pistons is moved into the back flush position first. As a result, the melt inflow of the corresponding filter is interrupted. A small melt stream of already purified material is diverted and passed backwards through the filter to be cleaned and discharged to the outside. Subsequently, this process is automatically repeated for the second filter.

| Filtertyp | Screen diameter [cm²] / [sqin] | Output [kg/h] / [lbs/h] | Screen diameter [mm] / [in] |

| CMF-2/058-BF |

2×27 |

2 x 4.0 |

50-10 |

110 – 220 |

58,3 |

2.3 |

|

CMF-2/076-BF |

2 x 45 |

2 x 7.0 |

80 – 195 |

176 – 430 |

76,3 |

3.0 |

|

CMF-2/096-BF |

2 x 72 |

2 x 11.2 |

130 – 290 |

286 – 639 |

96,3 |

3.8 |

|

CMF-2/116-BF |

2 x 106 |

2 x 16.4 |

190 – 430 |

418 – 948 |

116,3 |

4.6 |

|

CMF-2/125-BF |

2 x 122 |

2 x 18.9 |

220 – 490 |

485 – 1080 |

125 |

4.9 |

|

CMF-2/148-BF |

2 x 172 |

2 x 26.7 |

310 – 690 |

683 – 1521 |

148,3 |

5.8 |

|

CMF-2/176-BF |

2 x 244 |

2 x 37.8 |

430 – 980 |

948 – 2161 |

176,3 |

6.9 |

|

CMF-2/200-BF |

2 x 314 |

2 x 48.7 |

560 – 1260 |

1235 – 2775 |

200 |

7.9 |

| CMF-2/230-BF |

2 x 417 |

2 x 64.6 |

750 – 1670 |

1653 – 3682 |

230,3 |

9.1 |

| CMF-2/250-BF |

2 x 491 |

2 x 76.1 |

880 – 1960 |

1940 – 4321 |

250 |

9.8 |

| CMF-2/300-BF |

2 x 707 |

2 x 109.6 |

1270 – 2830 |

2800 – 6239 |

300 |

11.8 |

| CMF-2/340-BF |

2 x 908 |

2 x 140.7 |

1630 – 3600 |

3594 – 7937 |

340 |

13.4 |

| CMF-2/400-BF |

2 x 1257 |

2 x 194.8 |

2260 – 5030 |

4982 – 11090 |

400 |

15.7 |

The throughputs are essentially influenced by material, viscosity, filter fineness and degree of contamination.