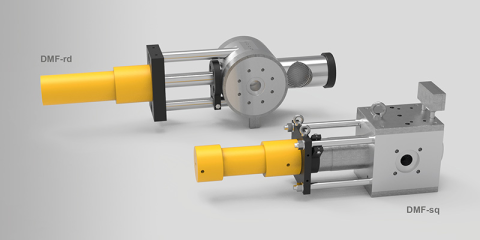

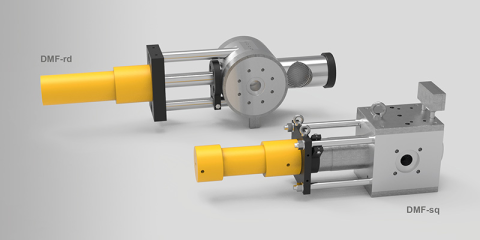

The discontinuously operating piston screen changers are used in production areas, where a short interruption of production for filter change is possible. They differ mainly in the shape of their housings.

The DMF-rd is a round case that is heated with ceramic heating bands. This filter is the most cost-effective filter version and is mainly used as a pre-filter for coarse contaminants, as a pump protection or used in reduced space conditions (co-extrusion).

The DMF-sq is suitable for higher temperatures (up to 350 ° C) and higher pressures (up to 500 bar) due to its square housing and is heated with heating cartridges.

Both types can be used for polyolefins, melt adhesives and for many engineering plastics too.

When a filter change is required, the screen carrier piston is hydraulically moved out of the housing which is activated by a hand valve, and will be returned to the housing after completed screen change. This requires a short break down in production.

| BritAS Filter | Screen diameter [mm] | Screen diameter [in] |

Screen area [cm²] | Screen area [sqin] |

Output [kg/h] | Output [lbs/h] |

| DMF-1/058-rd | 58,3 | 2.3 | 26 | 4.0 | 20 – 55 | 44 -121 |

| DMF-1/076-rd | 76,3 | 3.0 | 45 | 7.0 | 40 – 90 | 88 – 198 |

| DMF-1/096-rd | 96,3 | 3.8 | 72 | 11.2 | 65 – 145 | 143 – 320 |

| DMF-1/116-rd | 116,3 | 4.6 | 106 | 16.4 | 95 – 215 | 209 – 474 |

| DMF-1/125-rd | 125,0 | 4.9 | 122 | 18.9 | 110 – 245 | 243 – 540 |

| DMF-1/148-rd | 148,3 | 5.8 | 172 | 26.7 | 155 – 345 | 342 – 761 |

| DMF-1/058-sq | 58,3 | 2.3 | 26 | 4.0 | 20 – 55 | 44 – 121 |

| DMF-1/076-sq | 76,3 | 3.0 | 45 | 7.0 | 40 – 90 | 88 – 198 |

| DMF-1/096-sq | 96,3 | 3.8 | 72 | 11.2 | 65 – 145 | 143 – 320 |

| DMF-1/116-sq | 116,3 | 4.6 | 106 | 16.4 | 95 – 215 | 209 – 474 |

| DMF-1/125-sq | 125,0 | 4.9 | 122 | 18.9 | 110 – 245 | 243 – 540 |

| DMF-1/148-sq | 148,3 | 5.8 | 172 | 26.7 | 155 – 345 | 342 – 761 |

| DMF-1/176-sq | 176,3 | 6.9 | 244 | 37.8 | 220 – 490 | 474 – 1080 |

| DMF-1/200-sq | 200,0 | 7.9 | 314 | 48.7 | 180 – 630 | 617 – 1389 |

| DMF-1/230-sq | 230,2 | 9.1 | 417 | 64.4 | 375 – 950 | 827 – 2095 |

| DMF-1/250-sq | 250 | 9.8 | 491 | 76.1 | 440 – 980 | 970 – 2160 |

| DMF-1/300-sq | 300 | 11.8 | 707 | 109.6 | 630 – 1420 | 1389 – 3130 |

| DMF-1/340-sq | 340 | 13.4 | 908 | 140.7 | 810 – 1820 | 1785 – 4010 |

The throughputs are essentially influenced by material, viscosity, filter fineness and degree of contamination.