ABMFABMF - Automatic Belt Melt Filter

High regranulate quality at low operating costs and that fully-automatic – that is the ABMF series – automatic belt melt filter manufactured by BritAS GmbH.

High regranulate quality at low operating costs and that fully-automatic – that is the ABMF series – automatic belt melt filter manufactured by BritAS GmbH.

In order to filter contaminations effectively and efficiently out of plastics waste, in case of the BritAS filter, the filter fabric is fully-automatically changed. Thus, the regranulate quality remains constantly high and the contamination is discharged out of the machine with a very low loss of melt. By an intermediate container for the melt, the upstream extruder is permanently running.

The ABMF filter can be retrofitted from discontinuous to continuous.

Automated. Fully-automatic filtration.

The filter mechanics combined with the control provide for a fully-automatic,practical and cost-saving operation.

Clean. Very high filtration fineness.

Up to three filter belts can simultaneously be used. This allows an exact adjustment of different filter screen finenesses.

Permanent. Extruder operation during screen belt feed.

By storing temporarily the plastics melt, also during the screen feed, the extruder continues running and guarantees high process reliability.

Effective. Very high throughput rates.

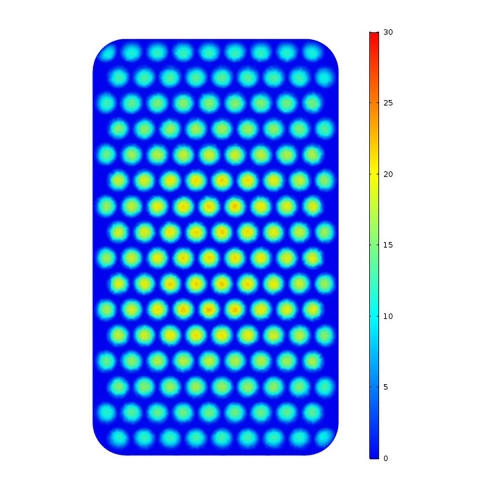

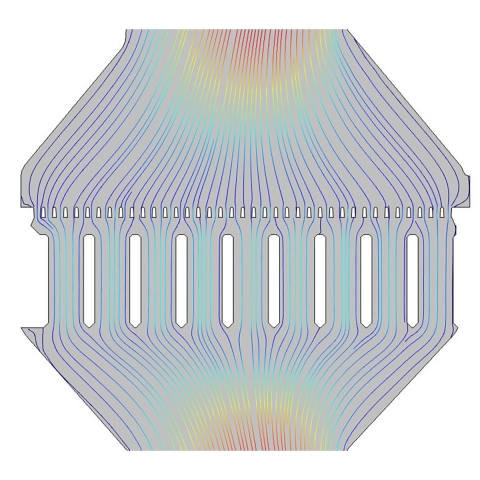

The new support plate design – consisting of grid and die plate – guarantees higher throughput, thus less pressure generation and more gentle processing.

Perfect. Homogeneity of the plastics melt.

The optimized flow channel improves the melt flow considerably again without material stress.

Efficient. Very low operating costs

Besides the automatic operation of the filter with high plastics throughput, the use of filter belts with dutch weave meshes ensures low operating costs at high output.

BritAS uses simulations as basis for product optimizations – example optimization grid and die plate

Suitable for post-consumer and post-industrial plastics waste and agricultural film.

Depending on the customer requirement, different materials, dimensions, weaves and tensile stren possible.

| BritAS Filter | Filter area [cm2] | Filter area [sqin] | Volume [Liter] | Volume [gal] | max. output [kg/h] | max. output [lbs/h] |

| ABMF-0570-07 | 570 | 88.4 | 7 | 1.8 | 900 | 1985 |

| ABMF-0570-09 | 570 | 88.4 | 9 | 2.3 | 1200 | 2646 |

| ABMF-0570-12 | 570 | 88.4 | 12 | 3.1 | 1500 | 3308 |

| ABMF-0750-09 | 750 | 116.3 | 9 | 2.3 | 1200 | 2646 |

| ABMF-0750-12 | 750 | 116.3 | 12 | 3.1 | 1500 | 3308 |

| ABMF-1050-09 | 1050 | 162.8 | 9 | 2.3 | 1200 | 2646 |

| ABMF-1050-12 | 1050 | 162.8 | 12 | 3.1 | 1500 | 3308 |

| ABMF-1050-15 | 1050 | 162.8 | 15 | 3.9 | 2000 | 4410 |

| ABMF-1050-19 | 1050 | 162.8 | 19 | 4.9 | 2500 | 5513 |

| ABMF-1600-12 | 1600 | 248 | 12 | 3.1 | 1300 | 2867 |

| ABMF-1600-15 | 1600 | 248 | 15 | 3.9 | 1600 | 3528 |

| ABMF-1600-19 | 1600 | 248 | 19 | 4.9 | 2000 | 4410 |

| ABMF-1600-25 | 1600 | 248 | 25 | 6.5 | 2700 | 5954 |

*Output values for LDPE depend on material and contamination.

High quality rPellets

Low operating costs

Fully-automatic

Modular design & platform technology

Generally, perfectly operating with agricultural film

The filter for post-consumer applications.